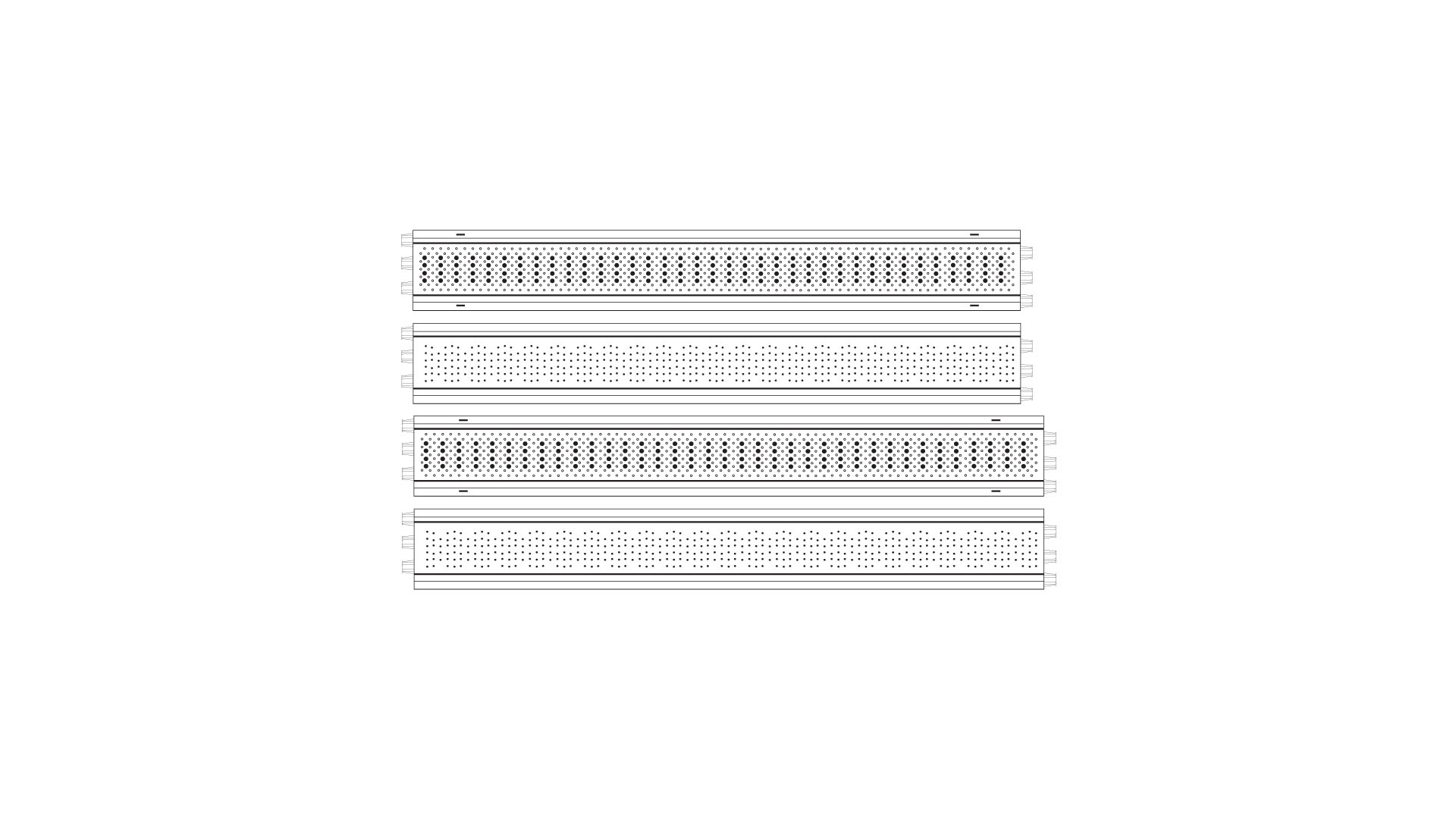

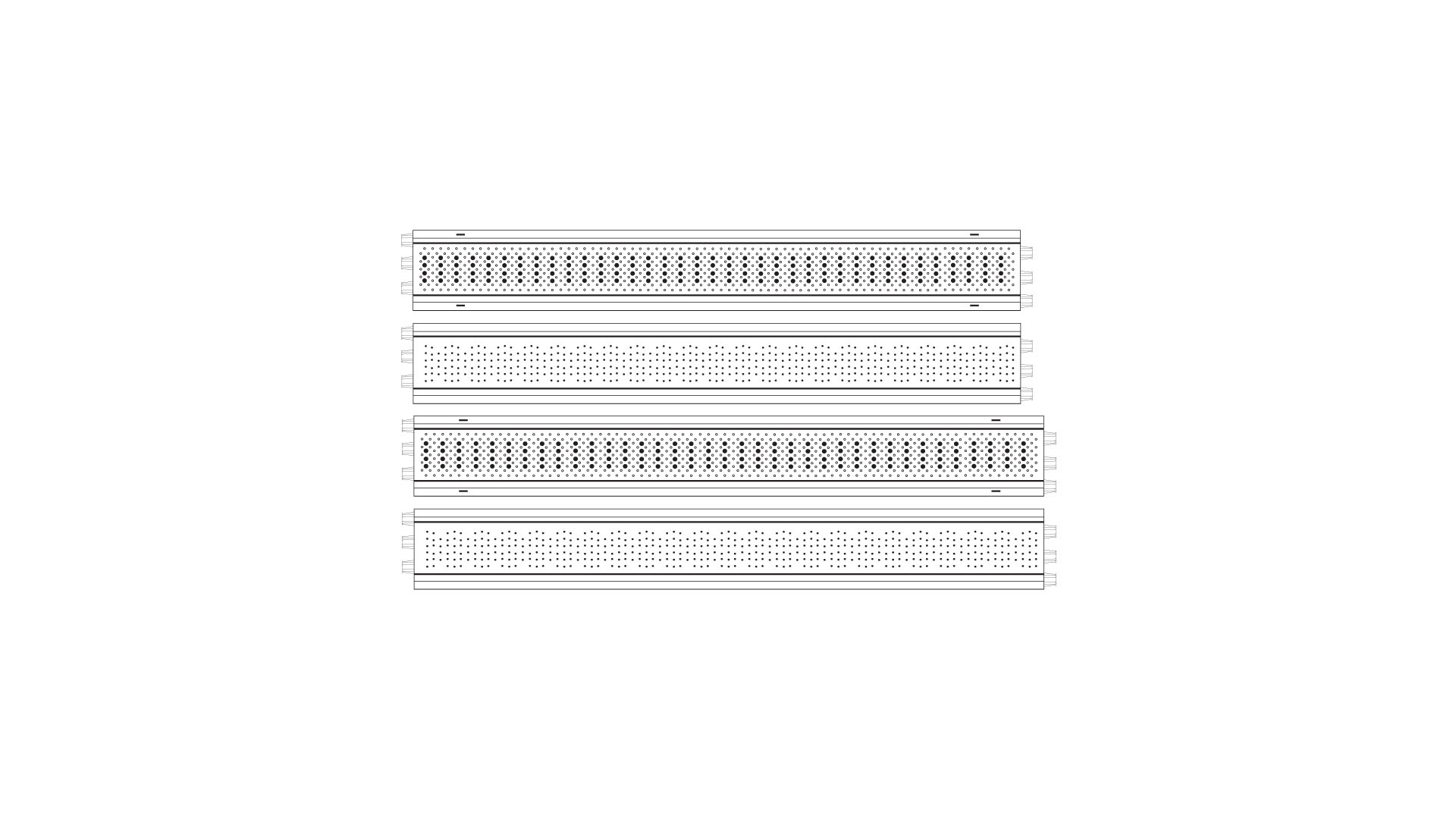

The deck is produced by a single cold-formed sheet. The “TP” mark results from embossing the hook fittings.

The deck is made up as follows:

- Galvanized sheet surface, 1 mm thick, S250GD, 494 mm wide and L long, with three folds forming three closed profile, which make up the decking level. The sheet creates a 60 mm high profile. The surface of the decking level has anti-sliding indentation, which produce an anti-slip effect.

- no. 2 hook fittings in sheet S250GD, 2.5 mm thick. A support surface and three ribbed hooks are cold-pressed on them, which can be attached with the transoms of the prefabricated frames. Hook fittings are then secured to the walking steel surface with 7 TOX points. Each hook fittings has a safety steel lock S250GD, made of 2.5 mm thick pressed sheet, and slides in a rail placed in the head. This steel lock is formed so that it cannot loosen after being assembled.

When sliding towards the extremity, the steel lock fastens under the transom with pressure, and prevents the deck to accidentally lift. On the contrary, when it slides inward of the deck, it releases the transom and allows for the removal of the deck. In both cases the position of the steel lock is stable and physical intervention is needed in order to change its position.

The disposal of contingent standing water is guaranteed by the presence on the surface of holes drilled every 108 mm. Contingent thin ice formations resulting from inevitable partial standing water do not exceed anti-slip indentations, which protrude 2 mm over the deck surface.

Depending on its length, the deck can achieve 6 class capacity (UNI EN 12811), corresponding to a load of 600 Kg/m².

The deck is produced in several sizes. 75 – 105 – 150 – 180 – 200 – 250-300.

The characteristics of the system are:

- Central reinforce with anti-slip indentations without sharp edges;

- Passage is facilitated by the support head with three hooks with lowered reinforcing ribs.

- Strategic positioning of surface-attaching points, in order to avoid significant bending due to the variation of load;

- High stability to longitudinal warpage guaranteed by the continued seam of the profile;

- Possibility to build decks up to 250 cm of length on traditional scaffoldings with 180 cm step.

- CL6 load, amounting to 600 daN/m², equal to twice the traditional CL4 decks, with 300 daN/m² capacity.

When sliding towards the extremity, the steel lock fastens under the transom with pressure, and prevents the deck to accidentally lift. On the contrary, when it slides inward of the deck, it releases the transom and allows for the removal of the deck. In both cases the position of the steel lock is stable and physical intervention is needed in order to change its position.

The disposal of contingent standing water is guaranteed by the presence on the surface of holes drilled every 108 mm. Contingent thin ice formations resulting from inevitable partial standing water do not exceed anti-slip indentations, which protrude 2 mm over the deck surface.

Depending on its length, the deck can achieve 6 class capacity (UNI EN 12811), corresponding to a load of 600 Kg/m².

The deck is produced in several sizes. 75 – 105 – 150 – 180 – 200 – 250-300.

When sliding towards the extremity, the steel lock fastens under the transom with pressure, and prevents the deck to accidentally lift. On the contrary, when it slides inward of the deck, it releases the transom and allows for the removal of the deck. In both cases the position of the steel lock is stable and physical intervention is needed in order to change its position.

The disposal of contingent standing water is guaranteed by the presence on the surface of holes drilled every 108 mm. Contingent thin ice formations resulting from inevitable partial standing water do not exceed anti-slip indentations, which protrude 2 mm over the deck surface.

Depending on its length, the deck can achieve 6 class capacity (UNI EN 12811), corresponding to a load of 600 Kg/m².

The deck is produced in several sizes. 75 – 105 – 150 – 180 – 200 – 250-300.